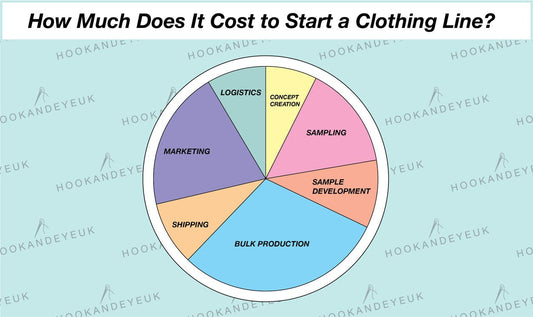

The industry is finally taking note of the REAL cost of fashion and I'm thrilled about it! Hookandeyeuk has been conscious of this since it's inception and I'm going to explain why...

Everyone thinks "I want my garments manufactured in the UK because I know it will be done 'properly' and I know the garment workers will be okay". Oh how wrong this can be...

Did you know that a large percentage of garment workers in the UK are paid WAY below UK living wages?!

Now to be clear, I'm not talking about sample seamstresses that are working on the development of garments, these garment workers often have well paid jobs in good conditions. I'm talking about the poor garment workers that are bashing out low unit quantities (around 20-300 units per design/colour). There is ample evidence for this and I've included the most relevant article I've found at the bottom of this post.

So, let's pull back the curtain of the real cost of cheap fashion...

THE REAL COST OF FASHION: 6 common misconceptions of garment manufacturing.

1. "Being based in the UK means everything is okay!"

Nope, not always. In the battle to offer lower and lower clothing prices, manufacturers are constantly looking to cut costs. Due to our cost of living being so much higher in the UK, it often means that, the only cost left that can be cut in the manufacture process are garment worker wages.

There are multiple reports of garment workers in the UK being paid £3.50 an hour! That's not enough to buy a pint in most places!

Now you might be thinking 'Hook and Eye UK'??

We are based in the UK meaning that we do all the designs, tech packs, pattern cutting, product review and development here, but since covid, the clothing manufacture industry in the UK has diminished drastically. Our sample and bulk manufacture construction is now done by our team in China. There just isn’t the fabric quality left here anymore sadly. China has a much bigger industry for it, and their technologies are so much better than ours so we made the move and couldn't be happier!

2. Anything made in China is made either under slave labour or made to low quality!!

Again, not always...and definitely not in our case! I'm not saying that China is perfect, no country is. I know there are places in China that do not fit with ethical practices, but if you've read this far then you'll know that's also true in the UK! The living wages in the UK are very high so a lot of UK manufacturers (especially in Leicester) pay their garment workers way less to make the construction costs less. At Hook and Eye UK, we will not be a party to this. All of our teams, whether they're based in the UK or China, get paid above Living wages and work in ethical conditions.

The below images show the Hook and Eye UK factory based in China..

These are actual photographs of our factory in China.

3. "I won't be able to communicate my ideas properly if I work with a manufacture team outside of the uk".

This isn't the case with Hook and Eye UK. We handle all communications in the UK and we then liaise with our overseas team! All you have to do is make sure the tech pack we create in our tech pack and design session is exactly how you want it!

These are actual photographs of our factory in the UK.

4. "Shipping costs add so much more onto my unit cost I might as well make my items in the UK'.

Yes and no. Yes shipping adds cost to your garment price but it only affects the total cost if you are manufacturing in the UK using very cheap fabric or with a manufacture company paying unethical, low garment worker wages.

Most fabric purchased in the UK is at a much higher cost than it is abroad (this is due to comparative living costs). As long as you're working with a reputable clothing manufacturer in the UK the living wage cost will be much higher too. This additional fabric cost along with the higher living wage usually averages out what you would be spending on shipping costs.

5. "Shipping garments from abroad adds to my environmental footprint'.

Considering environmental footprint in fashion is so important. So let's look in a bit more detail...

When thinking environmentally, we have to consider that most fabrics are made abroad (especially in China). These fabrics are shipped over to the UK via sea freight or truck. This means the fabrics have already made the journey prior to being made into clothing. But there's another important factor here...

As fabric cutting provides a lot of wastage it's actually more economic and efficient to ship pre-made garments than it is to ship the uncut fabric to the UK.

Another point to be made here is that NO cotton is produced (naturally) in the UK at all, our temperatures are too low for it to be grown here. The biggest producers of cotton (in the world) are China and India. So even if the fabric is made in the UK, the core fibres will have been shipped from overseas.

At Hook and Eye UK we have considered all of these things and have decided that the most environmentally friendly and economic way to get your garments to you is to have them made in China, where the core fibre is grown in an eco-friendly manner, in ethical working conditions.

6. "The quality of UK manufacture is much better than China or other overseas manufacturing countries".

Myth.

Quality level depends entirely on the factory itself and the quality level they work to or you request pricing to be based on. The higher the quality level of the manufacturing, the more work the manufacture company has to do and the more you will pay for your items to be manufactured.

There is no 'one' level of quality, but AQL (Acceptable Quality Level) is the most widely used term for quality levels in the clothing manufacturing industry. AQL levels in industry are set according to the number of defective items that could be accepted during an inspection:

HIGHEST : NOT ALLOWED (Meaning no defective items allowed)

LOWEST : 6.5 (Means more defective items are allowed)

We manufacture to a high commercial standard of 1.5. Most low unit clothing manufacturers produce to much lower standards than this, meaning lower quality garments!

We slot our smaller brands in-between our larger brands, allowing us to give everyone the same level of manufacture, no matter on the size of your brand!

Our honest environmental views:

We're a clothing design and manufacture company, and obviously we want people to design and manufacture more clothes.

Our environmental stand comes from making better quality clothes that last longer and therefore stop people from purchasing fast fashion 'throw-away' garments. The truest way to be environmentally friendly in any clothing brand is to up-cycle and resell pre-loved clothing. We know this isn't for everyone and this is why we offer our services. The idea is to manufacture clothes that, if looked after properly, will outlive the wearer!

Want to learn more? Here's a great article about the poor garment working conditions in the UK:

In conclusion:

If you want to consider the real cost of your clothing manufacture, the best thing you can do is really research the company you choose to manufacture your clothing.

Look at their reviews, ask to book consultation so you can visit their working areas and see conditions. Inspect their pricing and be realistic with yourself. If the construction price they give you is too good to be true, remember it usually is and someone in the chain is paying that price!

At Hook and Eye UK we manufacture for bridge brands mainly. These are brands like Stussy, Palm Angels, Fear of God etc. Brands that price their products at a mid level. Not value (like H&M), not High End (like Gucci). Working with brands at this level allows us to price garment construction ethically and allows you the brand owner to make the profits you need to grow your brand!

Love, Joss H&E xx

P.s We're here for you if you have questions drop us a WhatsApp on +447939591255