Updated Jan 2026

Whether it's a bold logo, an illustration, or a striking pattern, the right graphic applications can take your clothing brand to the next level. Graphic applications are a key part of garment aesthetics, brand identity, and perceived product quality and they influence customer satisfaction and long-term brand value. In this guide, we’ll explain the most common methods used in fashion production, when to choose each, and how they relate to production scale, fabric type, and design detail (industry practices supported by printing and textile standards).

Knowledge is always power when starting a fashion brand, and having a clear understanding of how different graphic applications work before you’ve even started designing your clothes will help you design in the right way for the look and feel that you’re trying to achieve (instead of designing a graphic and hoping it turns out how you want it to).

In this handy guide, we'll explore the different graphic application types used in the fashion industry, helping you choose the right option for your clothing brand.

Graphic applications serve as the artistic canvas for clothing designers, allowing you to transform simple garments into unique pieces with real character. But with various different techniques and methods available (each with their own pros and cons), the question is, which type of graphic application should you choose?

Let's run through your options:

Screen Printing & Puff Printing: Classic Methods for Bold Garment Graphics

Screen printing, also known as silk screen printing, is one of the most widely used methods for applying designs to clothing. This traditional technique has been refined over decades and remains preferred for vibrant, durable prints on cotton and many other fabrics. Screen printing uses ink that is passed through a mesh screen and then cured (usually with heat).

Screen printing can be flat (see the Jerry J image below on the left), or it can also be ‘puffy’ (see below right), also known as puff printing. Puff printing adds a foaming agent to produce raised, textured graphics that stand out visually.

Screen Print Pros and Cons

Screen print has exceptional durability, vivid colour saturation, excellent for bold graphics or logos however set up costs are higher (in comparison to DFT printing). It is also less cost-effective for designs with 6+ colors or very small production runs and commonly recommended for 50+ units and more premium garments (industry experience consensus).

Direct-to-Film (DTF) Printing – Affordable & Flexible for Small Runs

Direct-to-Film printing (aka DTF Printing) is a cost-effective option, especially for small clothing batches. This method combines flexibility with the capability to handle multi-colour designs without the screen setup costs of traditional screen printing. Check out our example below…

Direct-to-Film (DTF) Printing Pros and Cons

The design is first printed on a heat-transfer film and then pressed onto the fabric. The good thing is, it's relatively quick and affordable. Essentially it creates a washable sticker that goes onto your garment. The downside is that it doesn't provide the same level of durability as screen printing.

Direct-to-Garment (DTG) Printing: High-Detail Full-Colour Prints

DTG printing is a revolution in clothing design, allowing for full-colour, high-resolution designs printed directly onto your garments. Perfect for highly detailed artwork and photographic graphics it offers unmatched colour depth when compared to analog methods. DTG is widely used in small-batch fashion and custom apparel production, particularly for cotton-dominant fabrics.

Direct-to-Garment (DTG) Printing Pros and Cons

DTG offers awesome detail and colour reproduction but it's potentially less cost-effective, unless you're doing large production runs. It generally has an MOQ of 100 units per design. The choice depends on the complexity of your designs and your budget. DTG has a reputation for fading over washes however the technology is much better now and although the print will fade it will only fade along with the lifecycle of the base garment.

Embroidery for Clothing – Timeless & Durable Graphic Finishes

Timeless and durable. Embroidery is a classic graphic application method that involves stitching designs into fabric using thread. It offers a timeless, elegant look and great durability. Known for its tactile quality, embroidery is frequently used for logos, badges, and premium streetwear accents. The stitch choice and thread type directly influence durability and appearance.

There are two types of embroidery; flat or 3D. 3D embroidery is only suitable for less fiddly designs, but can give a really nice depth to your graphics.

Embroidery Pros and Cons

Selecting the right thread type and fabric is essential to ensure the longevity and quality of your embroidered designs. The choice of embroidery thread colours is pretty much limitless, however, the style of graphic needs to be bold enough for your embroidery to look good.

Sublimation Printing: All-Over, Vibrant Prints Mainly for Polyester Garments

Sublimation printing allows for vibrant, all-over designs on polyester fabrics. There are a few different sublimation methods, but essentially your design is printed over one side of your fabric leaving the inside blank. Sublimation results in long-lasting, vivid prints. This method is ideal for immersive, all-over prints and is especially durable because the ink becomes part of the fabric fibers, resulting in wash-resistant, vibrant graphics.

Sublimation Printing Pros and Cons

This method is mainly suitable for polyester fabrics, although there are sublimation methods that can be done on cotton fabrics. So if this is something you're keen on, choosing your fabric choice carefully is vital. We can help advise on this, or if you can click here to check out our range of fabrics.

Also bear in mind that sublimation printing method does not suit low MOQs. Generally the MOQ is around 100 units per design, so you need to be prepared to do bigger production runs.

Vinyl Printing: Matt, Metallic & Flock Options for Crisp, Clean Graphics

Vinyl printing involves cutting vinyl sheets into specific shapes or letters and then heat-pressing them onto the garment. It offers a good level of durability. Vinyl is available in a matt, shiny, metallic or flock look. Flock printing adds a luxurious, velvety texture to designs.

Check out the image below to see a few different styles of vinyl printing:

Vinyl Printing Pros and Cons

With vinyl cut printing, you can create crisp, clean designs, making it a popular choice for sportswear, uniforms, and promotional clothing. Usually best for single colour designs.

Raised Silicone Printing – Textured, Premium Graphics for Apparel

Silicone print requires making a mould for your design, filling it with silicone and then transferring this to a film. This premium method adds visual interest and is chosen for bold branding elements on jackets and streetwear pieces.

Raised Silicone Print Pros and Cons

Raised silicone offers a unique look to all other printing methods due to its raised effect, however it is only available in single colour and only in black and white in low units (anything under 500 per design/colour).

Embossing & Debossing Techniques for Subtle, Long-Lasting Graphics

Embossing or debossing is created by making a mould for your design and then applying this to the garment with heat and pressure.

Embossing / Debossing Pros and Cons

Embossing or debossing does not fade like other graphic applications as it is a part of the garment however the creation and development of the moulds are expensive for low units (anything under 200 per design over several colours), so if you're doing small production runs, this won't be the most cost-effective option.

Fabric Appliqué: Creative Multi-Material Graphic Applications

Appliqué is a technique where fabric pieces are sewn onto the garment to create designs. It allows for the incorporation of different textures and materials. This technique adds depth and texture and allows brands to mix materials for a more artisanal look.

Fabric Appliqué Pros and Cons

You can get really creative with appliqué, for example you can use contrasting fabrics or materials to make your designs truly stand out. This technique can be costly due to the additional labor costs of placing and sewing each appliqué therefore it is unsuitable for MOQ’s of less than 100 units per design.

Chenille Patches – Textured, Eye-Catching Embroidered Patches

Chenille is a type of embroidery that is added to patch to create a 'chenille patch'. Two yarns are woven together to create a slightly 'fuzzy' texture. It allows for the incorporation of different textures due to the mixture of the chenille weave, flat embroidery and the felt backing.

Chenille Patches Pros and Cons

Chenille patches are a good way to add texture to any design and the colour options for threads are almost limitless. This technique can be costly due to the additional labor costs of placing and sewing each patch, so it's not really suitable for MOQ’s of less than 100 units per design.

Rhinestone Heat Transfer – Sparkly, Decorative Graphics for Fashion

Custom rhinestone heat transfers are created by converting your design into circles, from which a mould is made. You then transfer diamantés into the mould and they are added to an adhesive film. This film is then transferred to your garment by a mixture of heat and pressure. This decorative technique delivers high fashion sparkle ideal for premium or runway-inspired pieces.

Brands like Juicy Couture are a great example of Rhinestone Heat Transfer in action

Rhinestone Heat Transfer Pros and Cons

Custom rhinestone heat transfers are a great way to add sparkle to your design. Rhinestone colours are available in many colours but most the common colours include silver, gold, black and iridescent.

This graphic application type is quite delicate due to the nature of the individual diamanté placements.

Garment Labels & Hang Tags – Branding, Care Info & Legal Essentials

Labelling and hang tags are not to be overlooked. They convey essential brand information and provide care instructions, legal information, and brand identity.

Important Considerations: Quality Control, Care Instructions & Compliance

Quality Control

Quality control is essential to ensure that the graphic applications on your clothing remain vibrant and intact after washing and wear, so make sure you're on it when you get your clothes manufactured. Here's a checklist to avoid costly mistakes when you get your clothing manufactured: garment manufacturing checklist.

Washing and Care Instructions

May sound obvious, but make sure you provide clear washing and care instructions to customers to prolong the lifecycle of your designs. Proper care helps maintain the integrity of the graphic applications so that your customers can enjoy your clothing for longer. Happy customers = a happy brand.

Legal Requirements

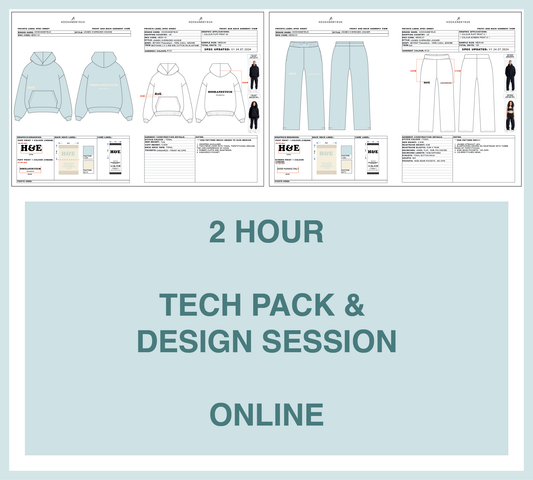

Ensure compliance with labelling laws to avoid legal issues down the road. Include fabric content, country of origin, and care instructions as required by law. In your tech pack and design session we will ensure you meet legal requirements on all labels so no need to worry too much about this.

Conclusion: Choose the Right Graphic Application Method Based on Your Design Needs & Production Scale

Choosing the right graphic application method for your clothing line is a crucial decision that has a huge impact on your brand's identity and customer satisfaction.

It's important to think about the nature of your designs, production scale, and budget when making your choice.

With the wide range of graphic application options available, you have the creative freedom to bring your fashion vision to life.

Whether you're aiming for a timeless embroidered look, a vibrant sublimation print, or a precise vinyl cut design, the right choice depends on your design goals and production requirements.

If you want some expert guidance on how to design your clothing line, just click here to book a design session with us.

FAQs

1. Are graphic applications limited to t-shirts and casual wear?

No, graphic applications can be used on a wide range of clothing items, including formal wear, activewear, and accessories.

2. Is embroidery suitable for delicate fabrics?

Embroidery can be adapted for delicate fabrics, but this requires many rounds of development to get right. Usual rule of thumb to get right in one go is to choose a heavier fabric and ensure that any text is at least 1 cm in height.

3. Can I combine multiple graphic application methods on one garment?

Yes, combining techniques like screen printing and embroidery can create unique and visually appealing designs however keep in mind that this can become costly over low units.

4. How do I choose between screen printing and DTG printing?

The choice between screen printing and DTG printing depends on factors like design complexity, production volume, and budget. Consider your specific needs when deciding between the two.

In this guide, we've explored a wide array of graphic application methods, each with its unique strengths and considerations.

If you’re unsure of which is best for your design don’t hesitate to ask our team at Hook and Eye UK, we’re always happy to advise.

Love, Joss H&E xx

p.s. If you'd like some guidance from us on your next clothing collection and you're new to Hook and Eye UK simply fill in our enquiry form here. The form will guide you through steps to see if we can help you and then tell you exactly how to contact us.

About the Author: Jocelyn Evans, owner of Hook and Eye UK, studied Fashion Design and Technology at Manchester Metropolitan University, including a year-long internship designing for Puma’s Team Sport division. After graduating, she worked with emerging grassroots brands in Birmingham and, in 2013, built a UK in-house design, sampling and manufacturing service that evolved into H&E. Recognising the limits of UK production, she expanded the business by pairing her UK team’s design, pattern cutting and sample expertise with overseas partners offering advanced fabric and construction technologies. Committed to transparency, sustainability and craftsmanship, Jocelyn creates only premium, long-lasting clothing—never fast fashion.