The world of clothing manufacturing is filled with unique terminology that can often be overwhelming for newcomers. Understanding these terms is essential for anyone involved in the fashion industry, whether you're a designer, manufacturer, or entrepreneur. This comprehensive guide will take you through the A-Z of clothing manufacturing terms, providing clarity and insight into each concept.

A – Appliqué

Appliqué refers to a decorative technique where a piece of fabric is sewn onto a larger piece to create a design or pattern. This method adds texture and visual interest to garments, making it a popular choice in fashion design. Appliqué can be used in various ways, from simple shapes to intricate designs, and is often seen in children's clothing and accessories.

B – BOM (Bill of Materials)

A Bill of Materials (BOM) is a comprehensive list detailing all the materials required to produce a garment. This includes fabrics, trims, labels, and any other components necessary for the final product. A well-structured BOM is crucial for manufacturers as it aids in cost estimation, inventory management, and production planning.

C – Cut and Sew

The cut and sew process involves cutting fabric into specific shapes and then sewing those pieces together to create a finished garment. This method is fundamental in garment production and allows for a wide variety of styles and fits. Understanding the cut and sew process is essential for anyone looking to enter the clothing manufacturing industry.

D – Dart

A dart is a folded and stitched wedge of fabric that helps shape a garment to fit the contours of the body. Darts are commonly used in women's clothing, particularly in suit jackets, blouses and dresses, to create a more tailored silhouette. Mastering the use of darts is vital for designers aiming to create flattering and well-fitted garments.

E – Embroidery

Embroidery is the art of decorating fabric using needle and thread or yarn. This technique can add intricate designs and patterns to garments, enhancing their aesthetic appeal. Embroidery can be done by hand or machine and is often used in both high-end fashion and everyday clothing.

F – Fabric Yield

Fabric yield refers to the amount of fabric required to produce a single garment, taking into account factors such as waste and shrinkage. Understanding fabric yield is crucial for manufacturers as it impacts cost efficiency and sustainability in production. Accurate calculations can help reduce waste and improve overall profitability.

G – Grading

Grading is the process of adjusting a garment's pattern to create different sizes. This involves scaling the dimensions of the pattern pieces while maintaining the design's proportions. Grading is essential for ensuring that a garment fits well across various sizes, making it a critical step in the manufacturing process. Below you can see the graded pattern for a kids t-shirt, each colour represents a different size.

H – Hand Feel

Hand feel describes the tactile quality or softness of a fabric when touched. This characteristic can significantly influence a consumer's perception of a garment. Fabrics with a pleasant hand feel are often more desirable, making it essential for manufacturers to consider this aspect when selecting materials.

I – Interfacing

Interfacing is a material used to add strength and rigidity to specific parts of garments, such as collars, cuffs, and waistbands. It can be fusible or non-fusible and is crucial for maintaining the shape and structure of a garment. Understanding the different types of interfacing and their applications is vital for achieving high-quality finishes.

J – JIT (Just-In-Time)

Just-In-Time (JIT) is a production strategy aimed at reducing inventory costs by receiving goods only as they are needed in the manufacturing process. This approach minimizes waste and storage costs, allowing manufacturers to operate more efficiently. Implementing JIT requires careful planning and coordination with suppliers. For low MOQ brands this is only avaible in the ‘print-on-demand’ model which uses low quality pre-made garments and printing techniques.

K – Knit Fabric

Knit fabric is made of interlocking loops of yarn, providing stretch and comfort. This type of fabric is commonly used in casual wear, activewear, and undergarments. Understanding the properties of knit fabrics is essential for designers and manufacturers to create comfortable and functional garments.

L – Lead Time

Lead time refers to the duration required from the placement of an order to the delivery of finished garments. This timeframe can vary based on factors such as production capacity, material availability, and shipping logistics. Effective management of lead time is crucial for meeting customer demands and maintaining a competitive edge. Below you can see an example of our general lead times.

M – Marker

A marker is a layout of pattern pieces on fabric used to optimise material usage during the cutting process. By arranging the pieces efficiently, manufacturers can minimise waste and reduce costs. Understanding how to create and use markers is essential for anyone involved in garment production. This can be done physically or digitally.

N – Notch

Notches are small cuts or marks on the edges of pattern pieces that indicate matching points for sewing. They serve as guides for aligning fabric pieces accurately during assembly. Properly placed notches can significantly improve the accuracy and quality of the final garment.

O – Overlock

An overlock stitch is a type of stitch that sews over the edge of fabric to prevent fraying. This technique is commonly used in garment construction and finishing. Overlocking can be done with a serger machine (also commonly known as an ‘overlocker’), which allows for quick and efficient stitching, making it a staple in clothing manufacturing.

P – Pattern

A pattern is a template from which the parts of a garment are traced and cut. Patterns can be created from scratch or adapted from existing designs. Understanding how to create and manipulate patterns is fundamental for designers and manufacturers alike.

Q – QC (Quality Control)

Quality Control (QC) is a process that ensures the final product meets defined quality standards. This involves inspecting materials, monitoring production processes, and testing finished garments. Implementing effective QC measures is essential for maintaining brand reputation and customer satisfaction.

R – Raw Edge

A raw edge refers to the unfinished edge of a fabric that may fray if not properly hemmed or serged, this can also be known as a ‘deconstructed hem or seam’. This aesthetic is often used in casual wear as a detail.

S – Sample

A sample is a prototype garment made to test fit, style, and construction before mass production. Creating samples allows designers and manufacturers to identify potential issues and make necessary adjustments. This step is vital for ensuring the final product meets design specifications and customer expectations.

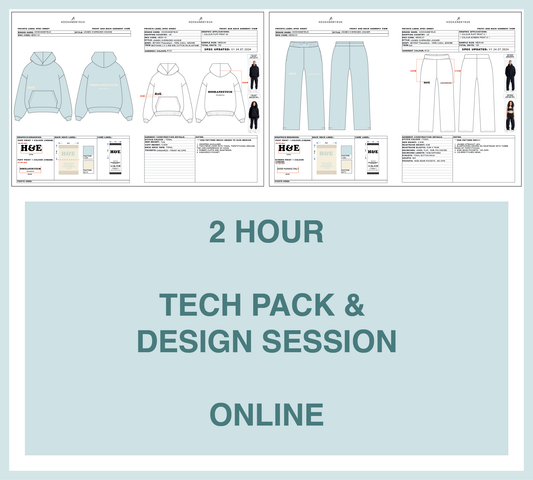

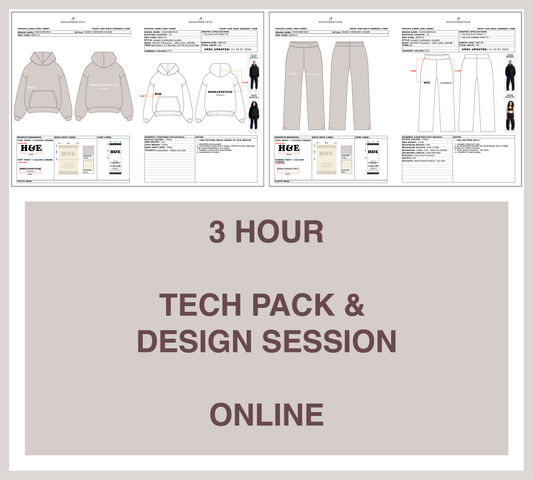

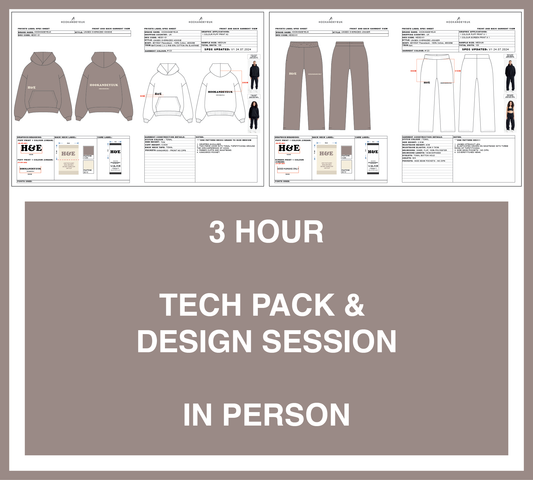

T – Tech Pack

A tech pack is a comprehensive document containing all the specifications needed to manufacture a garment, including materials, measurements, trims, and stitching details. Tech packs serve as a blueprint for manufacturers, ensuring that all parties involved have a clear understanding of the design and production requirements. See an example of a tech pack from Hook and Eye UK below.

U – Unfinished Seams

Unfinished seams mean the edge of a fabric that may fray if not properly hemmed or serged. Managing these are crucial for achieving a polished and professional finish in garment production. Techniques such as serging or binding can be employed to prevent fraying. Unlike raw edges, unfinished seams are very obviously not meant to be there and are a clear quality issue.

V – Viscose

Viscose is a type of rayon fabric made from regenerated cellulose fibres, known for its silk-like feel and drape. This fabric is often used in dresses, blouses, and linings. Understanding the properties of viscose is important for selecting the right materials for specific garment types.

W – Wash Test

A wash test is performed to check the colourfastness, shrinkage, and overall performance of a fabric after washing. Conducting wash tests is crucial for ensuring that garments maintain their quality and appearance after laundering. This step is essential for meeting customer expectations and industry standards.

X – X-Dye

X-dye is a dyeing technique where different fibres in a blended fabric absorb dye differently, creating a multicoloured effect. This technique can add unique visual appeal to garments, making it a popular choice for fashion designers. Understanding dyeing techniques is essential for achieving desired colour outcomes.

Y – Yarn Count & knit Gage

Yarn count is a number that defines the thickness of yarn, influencing the weight and texture of the fabric. This measurement is crucial for selecting appropriate materials for specific garment types. Understanding yarn count helps manufacturers achieve the desired drape and feel in their products. Knit gage is often calculated when working out how you want to knit to appear in knitted items (like beanie hats, jumpers etc).

Z – Zero Waste Pattern Making

Zero waste pattern making is a design approach where pattern pieces are created to use all the fabric with no off-cuts or waste. This sustainable practice is gaining popularity in the fashion industry as it promotes environmental responsibility. Embracing zero-waste techniques can enhance a brand's reputation and appeal to eco-conscious consumers.

Conclusion

This A-Z guide serves as a valuable resource for anyone involved in clothing manufacturing, from aspiring designers to seasoned professionals. By familiarising yourself with these terms, you can enhance your understanding of the industry and improve your communication with colleagues and suppliers. Whether you're creating a tech pack or discussing fabric choices, having a solid grasp of these concepts will undoubtedly contribute to your success in the fashion world.

If you're looking to dive deeper into clothing manufacturing or need assistance with tech packs, don't hesitate to reach out to us at Hook and Eye here. We're here to help you every step of the way!

Hope you found this helpful,

H&E team :)