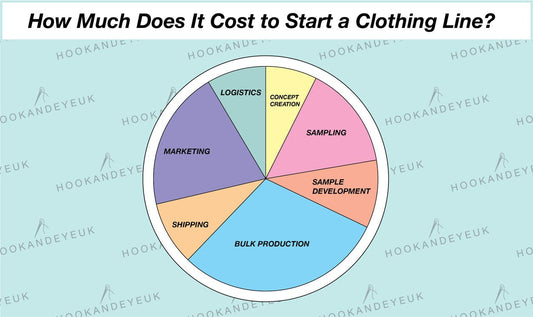

There are a vast number of garment manufacturers to choose from around the world, making the task of finding the right one for your brand feel overwhelming. This process requires a careful evaluation of several key factors, including production quality, cost-effectiveness, reliability, and lead times. Since each manufacturer has its strengths and specialties, it's important to prioritise what aligns best with your brand's values and goals. Extensive research, clear communication, and sample reviews can help identify the right manufacturer who can bring your vision to life.

Choose your brand level

As a new brand your RRP will be the biggest indicator to your customers as to what level your brand will sit within the industry. Start-up brands do not always have the luxury of high unit volume to drive down unit prices. There are 3 brand levels that sit within the fashion industry that you should consider when formulating your brand identity and marketing blueprint.

The 3 levels are:

Value – This level sits within the high street category. Brands such as JD, H&M, Mango and Next. Typically, this brand level sells fast fashion products and generally does not use the most eco-friendly production techniques as the RRP’s are very low and come with high volume commitment to fulfil the demand. £25 -£80

Bridge – While keeping the focus on high quality fabrics and construction techniques. Brands such as Represent, Lululemon, Joah Brown, Stussy, and Palm Angels are bridge brands that combine a mid-range RRP and luxury elements that allow them to price between £80 - £400.

High-end –Brands such as Gucci, Louis Vuitton, Prada and Alexander Wang sit at the high-end brand level and utilise premium quality fabrics, luxury finishings and carry household branding. £400 +

If you’re brand aesthetic is for value production level, you’ll need to choose a lower quality manufacturer to keep costs and units low. Hook & Eye UK focus on Bridge and High-end manufacturing as it allows us to offer premium quality at slightly higher units and keep our ethical and sustainable protocols. Our team focus on building a strong foundation to maintain the level of quality and assurance for all brands by having a highly skilled team that develops your tech pack patterns, and samples to ensure your bulk manufacture runs as smoothly as possible.

What are you looking for in your manufacturer?

When you set out to find the perfect manufacturer to bring your brand vision to life it is important that you ask yourself ‘what is important to you?’. Factors you could consider are Quality, MOQ (minimum order quantity), communication level, unit cost, good working conditions, fabric quality, garment construction quality, garment durability.

Also consider manufacturers that specialise in the products that you are designing i.e sportswear and tailoring would be from two different manufactures, the best results come from a specialised manufacturer that understand the requirements of the garment.

Once you have prioritised your non negotiables this will then give you a great idea as to what manufacturers are going to work for you and your brand. Talking to a range of manufactures will encourage a better understanding of what you will need to consider as not every manufacturer will be able to offer everything you would want on your list, but this should not discourage you from deciding on a manufacturer as some elements you can choose to compromise on.

The three main kinds of clothing manufacturer explained?

1. Design, manufacture & development – This is full-service manufacturing that will take care of every aspect of your brand development journey. You will achieve high-quality garments with the most ease. You will essentially have a team working on behalf of your brand, your garment developer will perform tasks including, tech pack development, checking measurement charts, pattern cutting generation, sampling development, sample reviews to ensure sampling meets your tech pack requirements, factory liaison to bulk production and delivery. With all aspects of your garment development journey taken care of by a professional, this will eliminate potential errors that can occur with a lack of understanding that can come with new brand owners.

2. Manufacturer sourcing – This is a step down from the full-service manufacturing process, you will work with a manufacturing sourcing agent that will take your tech packs and find the right manufacturer to fulfil your requirements. This method is slightly more cost-effective, but you can also run into communication blocks as you try to translate your vision through various cycles. Sometimes the agent will act on your behalf, but they are rarely experienced garment developers.

3. Direct to manufacturer – This is your most cost-conscious option as you are responsible for the entire development process, this will include supplying your own tech packs, patterns, measurement charts, sampling reviews, factory liaison, and shipping. This method is also time consuming when working to shorter deadlines or if this is your first experience working directly with a manufacturer. You are responsible for ensuring the success of this process.

Our top tip

Choosing a clothing manufacturer can be a timely task, it’s important to play to your strengths. Here’s some advice on how to approach this decision:

- If you are great at content creation and social media marketing: Focus on working with a manufacturer that can handle design, production, and development for you. This allows you to concentrate on building your brand and marketing it effectively. If you're great at creating buzz around your product, let a team of experts handle the technical side of things, so you can focus on the marketing that is the key to building a successful brand. A full-service manufacturing team could be great for you.

- If you have strong knowledge of garment construction and fabrics: You might prefer to work with a designer to create tech packs and then go to a manufacturing sourcing agent, who will find the right manufacturer for you. This gives you more control over the production process and allows you to get involved in the process and exercise your knowledge while keeping an overview of the garment development process.

- If keeping costs low is your top priority: You’ll need to dedicate time to learning the ins and outs of the manufacturing process to keep your unit costs down. You will experience some trial and error, but the key is to learn from those mistakes. This approach may involve more negotiation and research to find the best balance of cost and quality to understand what you are committing to.

Conclusion

If you made the list and decided to be a bridge or high-end brand and the most important factors were things like fabric quality, ethical and sustainable protocols and easy communications then Hook and Eye UK could be the right team for them, don’t hesitate to get in contact here.

Love Team, Hook and Eye UK