Any brand owner should consider the impact they have on the environment and everyone involved in the supply chain.

It’s very easy to feel detached from the whole supply chain process, certainly as a consumer (but also as a brand owner), when it doesn’t necessarily immediately occur to everyone HOW the items you wear got to the shop in the first place, as most often the fabric production, sourcing and garment manufacture is done overseas and you don’t witness it in person (out of sight out of mind).

We often get asked by our brand owners what measures we take to be eco-friendly and ethical – and we love you for it – because it shows you care just as much as we do!

At Hook and Eye UK we adhere to as many ethical and sustainable practices as possible in premium-quality low-unit garment manufacture, read on to find out how.

Factory conditions and staff wages

The design, pattern cutting and development part of Hook and Eye UK’s services happen here in our UK studio, and our manufacturing team is located in China. All of our staff across both the UK and international teams receive living wage or above, work in good, safe, working conditions, and our integrated China team have industry-leading audit certifications from SEDEX, The Certification of Quality Management System, and Alibaba Gold Plus Supplier Certificate – SGS. An audit is an in-depth evaluation of a manufacturing facility to assess the working environment and practices. Factories should have regular audits to certify workplace safety, workers rights etc.

This is what we imagine when we think about where our garments are made (which is similar to the Hook and Eye UK teams working environment):

Unfortunately garment workers are the main ones to pay the price for low unit prices (especially in low MOQ's), often working in unethical dangerous like the below..

Fabrics

All of our fabrics are sourced in China to reduce travel footprint. This means the fabrics have less to travel to get from the fabric mill to our manufacturing site.

We only offer premium quality fabrics (that last, and are REACH compliant).

What is REACH compliant? Essentially, REACH is an EU regulation designed to make sure textiles are free from hazardous chemicals that could harm human health or the environment. By complying with REACH, brand owners can have piece of mind that their products are safe to use.

We can also offer fabrics including recycled, organic and eco-friendly options with certifications such as GOTs and BCI.

What is GOTS? The Global Organic Textile Standard (GOTS) is the worldwide leading textile processing standard for organic fibres, including environmental, human rights and social criteria, backed up by independent third-party certification of the entire textile supply chain.

What is BCI? The Better Cotton Initiative was created to improve global cotton production for workers and the environment, growing it better for the future of the industry.

Quality of manufacture

We don’t believe in fast fashion and only offer premium quality garment construction methods to make styles that last. We have in-depth quality checks and reports to spot any manufacturer errors. All of our samples are reviewed by an experienced product development team member to recommend any areas for improvement moving forwards to bulk production.

To learn more about quality standards in garment manufacture, check out the section on AQL’s (acceptable quality levels), in our blog post here.

Less Samples

This one might sound strange at first, but it doesn’t mean you’re getting less value, you’re just getting where you need to more efficiently! What I mean by this is, no-one wants to be stuck in a lengthy sampling back-and-forth, doing rounds and rounds of sampling to get your design right; it uses a lot of time, resources and money. Some sample development is expected, it’s all part of the process of bringing a new idea to life, but there are several things we do to reduce the amount of sampling required.

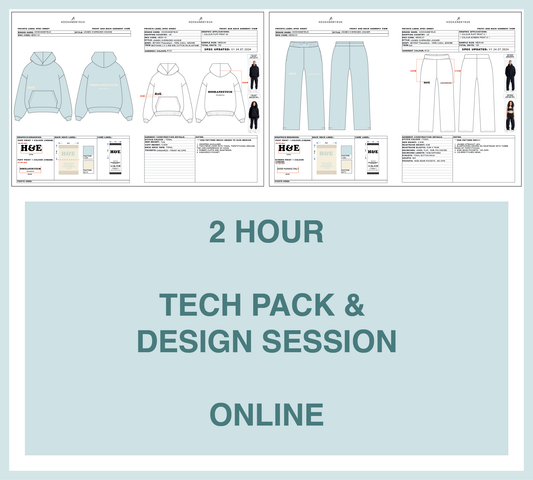

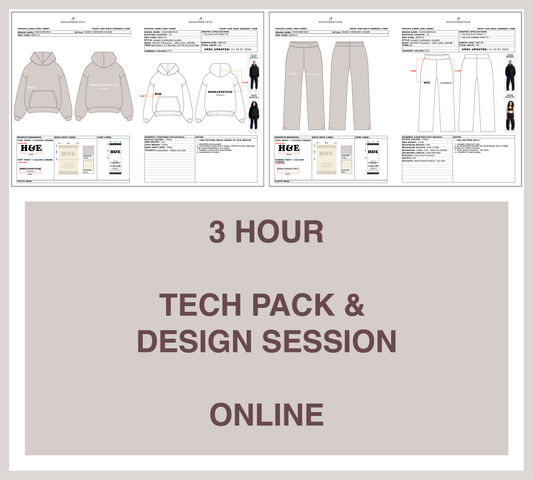

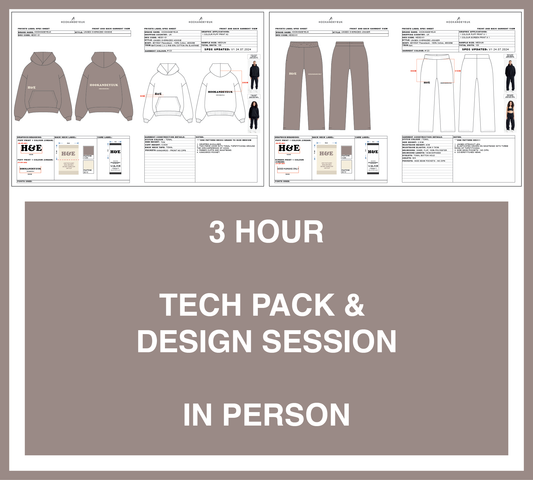

Number one is creating tech packs live in front of you (see an example of what one of our clothing tech packs looks like below); our designer will create for you (the brand owner or artic director), one-on-one with you. The tech pack & design sessions are specially designed to act as an efficient consultation to get every detail noted in the tech pack, building a solid foundation to get your sample as close to perfect as possible in one go to reduce textile and financial waste.

Next up is pattern cutting, and to reduce the amount of fit development needed, we use a fit reference as a starting point. This can either be one of our pre-developed styles (find out more here), or an item of clothing you own. What this does is cut out a huge amount of fit development, as your starting point has already been tried on by yourself or seen on models, and often just needs small tweaks to make it your own. A digital pattern is then created by our pattern cutter. This method of achieving your fit is much more accurate than using measurement charts, our blog here explains it perfectly.

Once you do have your first samples back, included in our sample development process is a free, live development session between yourself as the brand owner, and our garment developer, who is trained in finding clever pattern cutting and garment construction solutions to reduce the amount of sampling required. This is an opportunity to discuss any minor sample adjustments and give your garments the green light for bulk production!

Bulk production

Our bulk manufacture unit quantities run on a +/-5% system to allow for the least garment and fabric wastage possible. This means that you may receive up to 5% below, or 5% above, the bulk quantity requested. This is perfectly normal practice within the garment industry and is done to allow for QC (quality control) inspection and to reduce garment wastage. It is expected that not every single garment will pass QC inspection - clothing is human-made and errors happen. Having this 5% allowance ensures that every viable piece of clothing is always used and no energy is wasted trying to make to the exact number. It's worth noting that any fixable mistakes are also corrected at this stage, again helping to reduce textile waste and deliver error-free garments.

Shipment

We offer 6 week sea shipment to all brands whose order falls over the minimum weight requirement for sea freight (100kg – that’s about 100 hoodies). Sea freight is slower than air freight, but can accommodate higher volumes and has a much lower carbon footprint.

In Conclusion

Creating any new product is a development process and always has an impact, however following the practices above allow us to manufacture with as much transparency as possible and create garments that last. We pride ourselves in not offering 'fast-fashion' garment manufacture and endeavour to consistently reduce waste within all our processes.

Love, Bethany

Hook and Eye UK