Quality is at the heart of every successful fashion brand, but producing garments that look good, feel good, and meet customer expectations requires more than just creative design. Behind the scenes, two systems work together to maintain standards: Quality Assurance (QA) and Quality Control (QC).

Although the terms are often used interchangeably, they refer to two very different parts of the production process. Understanding both can help new and emerging fashion brands avoid costly mistakes and maintain consistency as they scale.

Quality Assurance (QA): Building Quality Into the Process

Quality Assurance is the part of garment manufacturing that ensures quality is designed into the workflow from the beginning. Instead of checking the garment after it is made, QA looks at the steps leading up to production and ensures everything is set up correctly.

Think of QA as your brand’s insurance policy; if the processes are sound, the chances of errors are significantly reduced.

What QA Focuses On

- Establishing clear production standards

- Setting up reliable methods and sequences for every task

- Ensuring workers understand the techniques and specifications

- Verifying that fabrics, trims, and tools meet requirements

- Eliminating risk points before garments are made

QA exists to create a smooth, predictable production environment where quality happens naturally.

Examples of QA in Garment Making

- Reviewing fabric and trim specifications to ensure they match the tech pack

- Checking the accuracy of patterns and grading before they go to cutting

- Confirming that sewing machines are adjusted to the correct tension

- Preparing detailed SOPs for sewing, finishing, and handling

- Updating garment makers on new designs or techniques before bulk production begins

Every QA activity aims to minimise surprises once production starts.

- QA processes typically align with ISO 9001:2015 quality management guidelines.

- Fabric, colourfastness, and shrinkage verification often rely on AATCC testing standards.

- Technical teams frequently use structured tools such as Failure Mode & Effects Analysis (FMEA) to prevent process errors.

Quality Control (QC): Checking the Finished Work

While QA focuses on preventing issues, Quality Control is responsible for spotting any defects that may still occur. Even with a strong QA system, issues can arise during stitching, finishing, or handling, and QC acts as the safety net.

QC examines the physical garment to determine whether it meets the required standards.

What QC Focuses On

- Inspecting garments during production

- Assessing the final product for compliance

- Identifying faults such as incorrect stitching, uneven seams, or faulty trims

- Separating defective pieces for repair or rejection

- Ensuring only approved garments are shipped

QC ensures the final product reflects the brand’s expectations before it reaches your customer.

Examples of QC in Garment Making

- In-line inspections to catch issues early, such as skipped stitches or puckering

- Measurements taken against the sizing chart

- Final checks for loose threads, stains, misaligned labels, or uneven hems

- Verification of packaging accuracy, including barcodes and care labels

- Approval or rejection based on sampling standards

QC focuses on what has been produced, not the method used to produce it.

- QC inspections often follow AQL sampling standards such as ISO 2859-1.

- Common garment defect classifications reference ASTM standards for textile evaluation.

- Brands may use digital QC software such as Inspectorio or Pivot88 to document inspection results.

How QA and QC Work Together and Why Both Matter

Although QA and QC are different, they are two halves of the same quality system.

- QA deals with “How do we ensure this doesn’t happen?”

- QC deals with “Did the finished garment meet the standard?”

Together, they create a cycle of continuous improvement.

Here’s how they complement each other:

1. QA prevents problems, QC confirms the outcome

QA ensures the right method is used. QC ensures the result is correct.

2. QA happens first, QC comes last

QA is part of early planning and mid-production, whereas QC occurs during stitching and after the garment is finished.

3. QA protects your brand, QC protects your customer

QA ensures your production partner follows proper practices.

QC ensures the buyer receives a garment free of defects.

4. QA improves efficiency, QC ensures accuracy

Brands that invest in QA avoid unnecessary revisions, rework, and delays.

QC adds the final level of precision before garments are packed.

Industry research from McKinsey’s State of Fashion reports indicates that quality failures are a top driver of returns in online apparel.

Studies cited by Textile Exchange show that quality consistency reduces waste and improves supply chain sustainability.

Both are essential to maintaining reliability, consistency, and trust, especially for new and growing brands.

Why This Matters for Emerging Fashion Brands

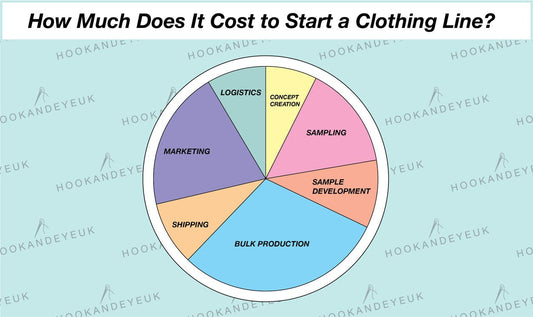

For start-ups or designers building their first collection, QA and QC can feel technical, but they make an enormous difference.

Brands that understand QA and QC are better equipped to:

- Choose the right manufacturing partners

- Ask the right questions during production

- Avoid expensive mistakes caused by preventable errors

- Reduce returns due to incorrect sizing or finishing

- Maintain consistent quality as they scale

And for a brand selling online, consistency is everything. One poorly made garment can lead to bad reviews, higher return rates, and damage to brand reputation.

Research shows that robust QA/QC systems can reduce defects by 30–60% and cut production costs by up to 20%.

How Hook and Eye UK Supports Quality Across Every Stage

At Hook and Eye UK, quality is an integral part of our development and production approach.

We support brands by ensuring:

Strong QA foundations

- Accurate tech packs and detailed specifications

- Reliable pattern development

- Clear production instructions

- Transparent communication with factories

- Sampling stages designed to identify issues early

Thorough QC oversight

- Checks at the sampling stage

- Guidance on what to review in pre-production and bulk samples

- Support in identifying stitching or construction issues

- Advice on evaluating fabric, finishing, trims, and fit

Our workflow benefits from recognised quality tools such as digital QC platforms and ISO-aligned production methods. We work closely with brands from concept to delivery. We have extensive QA and QC processes to create consistent, high-quality results.

Ready to Produce High-Quality Garments With Confidence?

Quality doesn’t happen by accident; it’s the result of the right processes, the right oversight, and the right production partner.

At Hook and Eye UK, we help fashion brands transform their ideas into beautifully made garments with strong QA and QC foundations built into every step.

Whether you're launching your first collection or scaling an existing line, our team can guide you through development, sampling, and production with clarity and expert support.

Book a consultation with Hook and Eye UK today and take the next step toward producing garments that meet professional standards every single time.

Hope you found this helpful,

H&E team :)

About the Author: Jocelyn Evans, owner of Hook and Eye UK, studied Fashion Design and Technology at Manchester Metropolitan University, including a year-long internship designing for Puma’s Team Sport division. After graduating, she worked with emerging grassroots brands in Birmingham and, in 2013, built a UK in-house design, sampling and manufacturing service that evolved into H&E. Recognising the limits of UK production, she expanded the business by pairing her UK team’s design, pattern cutting and sample expertise with overseas partners offering advanced fabric and construction technologies. Committed to transparency, sustainability and craftsmanship, Jocelyn creates only premium, long-lasting clothing—never fast fashion.