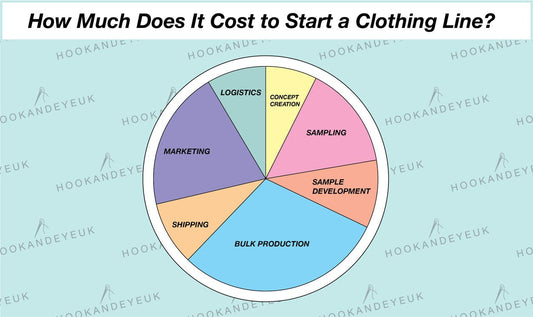

A tech pack is the blueprint of your garment, the document that tells your manufacturer exactly how to bring your design to life. For new designers and small fashion brands, creating your first tech pack can be both exciting and overwhelming. But mistakes in this document can lead to costly sampling rounds, delays, frustration, and misunderstanding between you and your factory.

At Hook and Eye UK, we see these issues often. As a UK-based garment development and manufacturing company offering 1:1 Tech Pack & Design Sessions, we work with brands worldwide helping them create professional, factory-ready tech packs that reduce errors and speed up production.

To support you in getting it right the first time, here are the top 10 mistakes to avoid in your first tech pack and how to fix them.

1. Mistaking a Mock-Up for a Tech Pack

One of the most common errors is sending a manufacturer a Canva mock-up, fashion sketch, or drawing with a few notes and assuming it's enough.

It isn’t.

Above you can see an example of a mock up.

A tech pack is a technical manufacturing document, not a design mood board or a line drawing on it’s own. Manufacturers need clear, structured information, not interpretation.

A complete tech pack should include:

- Black-and-white line drawings with stitching details

- Colour flats

- Fabric and trim specifications

- Construction notes

- Specific deatil measurements

- Colourways

- Labels and packaging information

- Any extra instructions for finishing or embellishment

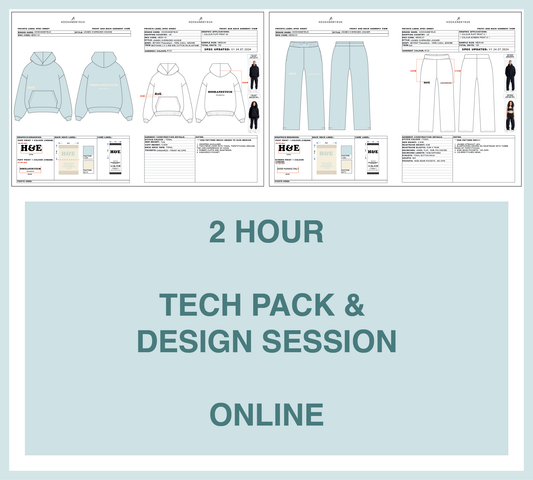

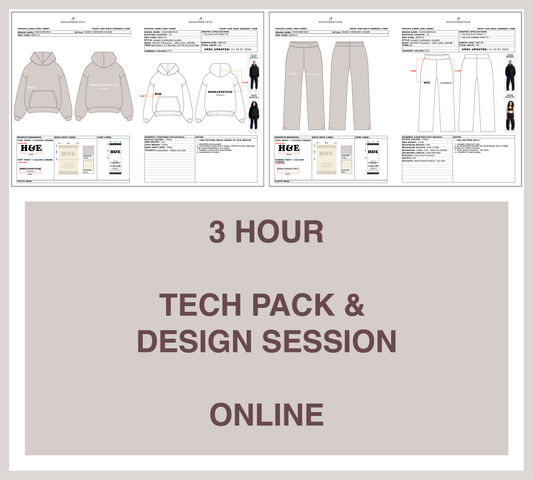

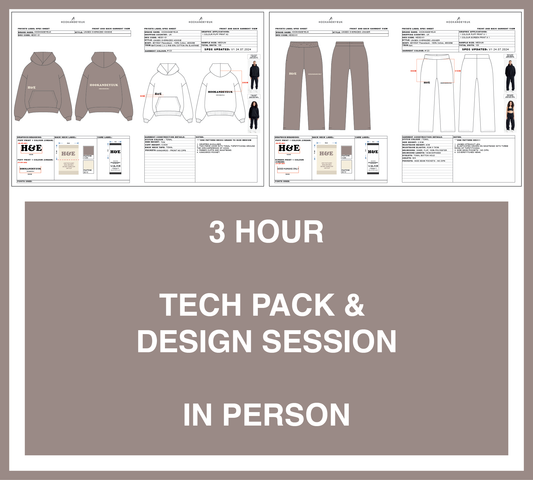

At Hook and Eye UK, our Tech Pack & Design Sessions provide all of these elements, delivered in PDF and editable vector formats, created by an industry-trained designer.

2. Creating a Measurement Chart Without Technical Knowledge

Another frequent mistake is attempting to build your own measurement chart without the right training. Measurement errors are one of the biggest reasons new brands experience multiple rounds of sampling.

If you’re not confident with measurements, it’s far more effective to provide:

A physical garment reference in a similar fabric to the fit you want to achieve.

From this, a skilled manufacturer (including Hook and Eye’s own production team) can create an accurate custom digital pattern, saving time, money, and guesswork. Note that once your sample fit is approved a full measurement chart can then be made to create your full range of sizing.

3. Unclear or Incomplete Line Drawings

Line drawings are the visual language of a tech pack. If they’re vague, cluttered, or missing stitching details, your manufacturer may misinterpret construction steps.

Examples of missing details include:

- Incorrect or unclear stitching types

- Missing panel lines

- Pocket construction not shown

- Rib placements or seam types not defined

Hook and Eye UK specialises in precise, clean technical drawings, ensuring pattern cutters and garment workers can follow every detail with confidence. See an example below.

4. Conflicting Information Within the Document

A tech pack must be internally consistent. When different pages contradict each other, the factory won’t know which instruction to follow.

Common conflicts include:

- Measurements that differ from one page to another

- Colour names or graphic codes do not match between sections

- A construction method is shown differently in two diagrams

Confusing instructions slow down production and increase the risk of errors. Always cross-check.

5. Only Including a Coloured Line Drawing

Coloured drawings are great for showing the aesthetic, but they don’t give enough technical clarity.

Manufacturers need black-and-white flats because they clearly show:

- Stitching

- Panel lines

- Construction details

- Seams and folds

Every tech pack must include both.

6. Not Creating Separate Tech Packs for Each Colourway

Each colourway should have its own dedicated tech pack, even if the style is the same.

Why this matters:

- Fabric colours may change

- Trims, cords, labels, and thread may need different colour matches

- Some shades dye differently and need different handling

A combined document often leads to colour mistakes in bulk.

7. Not Stating Expected Bulk Quantities

Manufacturers need clarity on quantity early because it determines:

- Whether they can take on your order

- Whether you meet their MOQ

- The factory capacity needed

- Your final price

Hook and Eye UK offers low MOQ production support, but the manufacturer still needs estimated numbers at the tech pack stage.

8. Forgetting Packaging and Labelling Requirements

Packaging and labelling are part of production, not something to figure out at the end.

Every tech pack should include:

- Label design

- Label placement

- Care label instructions

- Packaging specifications (if required)

These details ensure consistency, especially in bulk production. See an example of labelling requirements below.

9. No Version Control or Revision History

If you send updates without version numbers, your manufacturer may use the wrong file, a mistake that can cost time and money.

Include a revision table with:

- Version

- Date

- What changed

This keeps everyone aligned throughout development.

10. Sending the Tech Pack Before It’s Ready

Rushing the tech pack just to “get production started” almost always leads to more delays.

Before sending, check:

- Are all drawings clear?

- Are specific detailing measurements accurate?

- Are fabric and trim details finalised?

- Are colourways correct?

- Does every section match?

A polished tech pack speeds up sampling dramatically.

How Hook and Eye UK Supports You

Hook and Eye UK is more than a tech pack service; we are a full garment development team based in the UK, supporting brands internationally with:

- 1:1 Tech Pack & Design Sessions

- Professional line drawings and measurement sheets

- Factory-ready documents

- Low-MOQ manufacturing services

- Pattern development, sampling, and production

- Ethical manufacturing partners that are committed to safe working conditions and fair pay

Our goal is simple:

To help new and growing brands avoid costly mistakes and move confidently from concept to production.

Ready to Create a Professional, Factory-Ready Tech Pack?

Whether you're building your first collection or refining your development process, we can help you produce accurate tech packs that eliminate guesswork and minimise sampling rounds.

Book a Tech Pack & Design Session with Hook and Eye UK and start your production journey with clarity and confidence. If you’re not based in the UK that’s not a problem, we work with brands worldwide from the USA and Australia to Germany, Poland, Senegal, Canada and the UAE and much more.

Hope you found this helpful,

H&E team :)