If you're starting your own brand, you'll need to know about clothing manufacture MOQ's (Minimum Order Quantities) and what it means for your designs and your business. Don't worry, we've got you covered!

MOQ (Minimum Order Quantity), is a term that you will come across when you start looking into manufacturing your clothing designs. There are several different factors that affect what the MOQ will be for each design; in this article we’re going to explain them for you!

What Does “MOQ” Mean? Understanding Minimum Order Quantities

MOQ basically means the minimum amount of garments you are allowed to order from your clothing manufacturer per design.

Why Clothing Manufacturers Set Minimum Order Quantities (MOQs)

Setting an MOQ is all about maximising efficiency in the manufacturing process. Clothing manufacturers make your garments in bulk – meaning that they produce one lot all together. This makes the process much more economic and efficient for them. The higher the bulk quantity, the more cost-effective the production is, that's because the set up only needs to be done once and they create a very streamlined process.

Think about baking a batch of cupcakes – you’ve already created the recipe, bought the ingredients, set up the equipment – it now makes more sense to bake an entire batch rather than just one right?

It’s the same for garment manufacture; the bulk quantity needs to be worth all that preparation and set up cost.

The more complicated the manufacture, the higher the MOQ gets, as it involves more set up and work from the factory.

MOQ vs. Sampling: Why You Can Order Samples Before Bulk

Of course, any factory CAN make fewer units, after all, they make samples (which are one-off garments). But when a factory takes on creating a sample, they are anticipating that a bulk order will follow, and sampling is a necessary process to get ready for bulk production. A lot of planning and preparation happens before bulk manufacture actually begins.

There’s a reason why your sample costs much more than your bulk production unit price. When a manufacturer makes a sample, there’s a lot of preparation and work that has to go into it, because they haven’t made that specific design before. A pattern will need to be made, fabrics and any trims and components sourced, and a construction plan created. Any graphic applications need to be set up, this might require creating specific digital files, screens or molds. The manufacturer is basically figuring out how to make it and testing it before bulk production.

Your bulk unit price will then be cheaper than the sample cost, because all the sourcing, development and sampling has already been done and any problems ironed out. Some fixed costs though, like production set-up and factory overheads, remain the same, so that's why MOQ's are set; to make sure the preparation and labour is worth the order amount.

Low vs. High MOQ — What’s Standard for Clothing Manufacturing?

There are no set boundaries for what classes as a low or high MOQ in the clothing industry, it all depends on what the individual manufacturer is willing to take on. A manufacturer has to consider factors such as set up, labour and overheads and make sure that an order is viable for them.

Some bigger factories will not even consider taking on a job below 1000 units, whereas smaller factories will normally be happy to complete smaller bulk orders.

At Hook and Eye UK we are considered low unit manufacturers as our MOQ generally starts at 50 units, depending on the complexity of the garment.

Factors That Impact Your MOQ: Fabric, Construction, Prints & More

So, how is the MOQ decided? The minimum order quantity for a garment is affected by a few different factors. It's a good idea to bear these in mind when you're designing your clothing ranges, that way, you'll know what unit quantities to expect and how certain design features that you add may affect the MOQ.

Construction Complexity — How It Raises Your MOQ

The more complicated a garment is to make, the higher the MOQ will be. Features like panelling, layering, lacing and fly front zips are all factors that increase the minimum order quantity.

If you consider, for example, the amount of work that goes into a simple t-shirt, vs a pair of cargo trousers with a zip front and several patch pockets. The amount of work to make the cargo trousers is significantly higher than the simple t-shirt, and that extra work needs to be factored into the production line.

Let’s look at a breakdown below of what types of clothing might fall into our MOQ levels for clothing manufacture here at Hook and Eye UK (per design/colour):

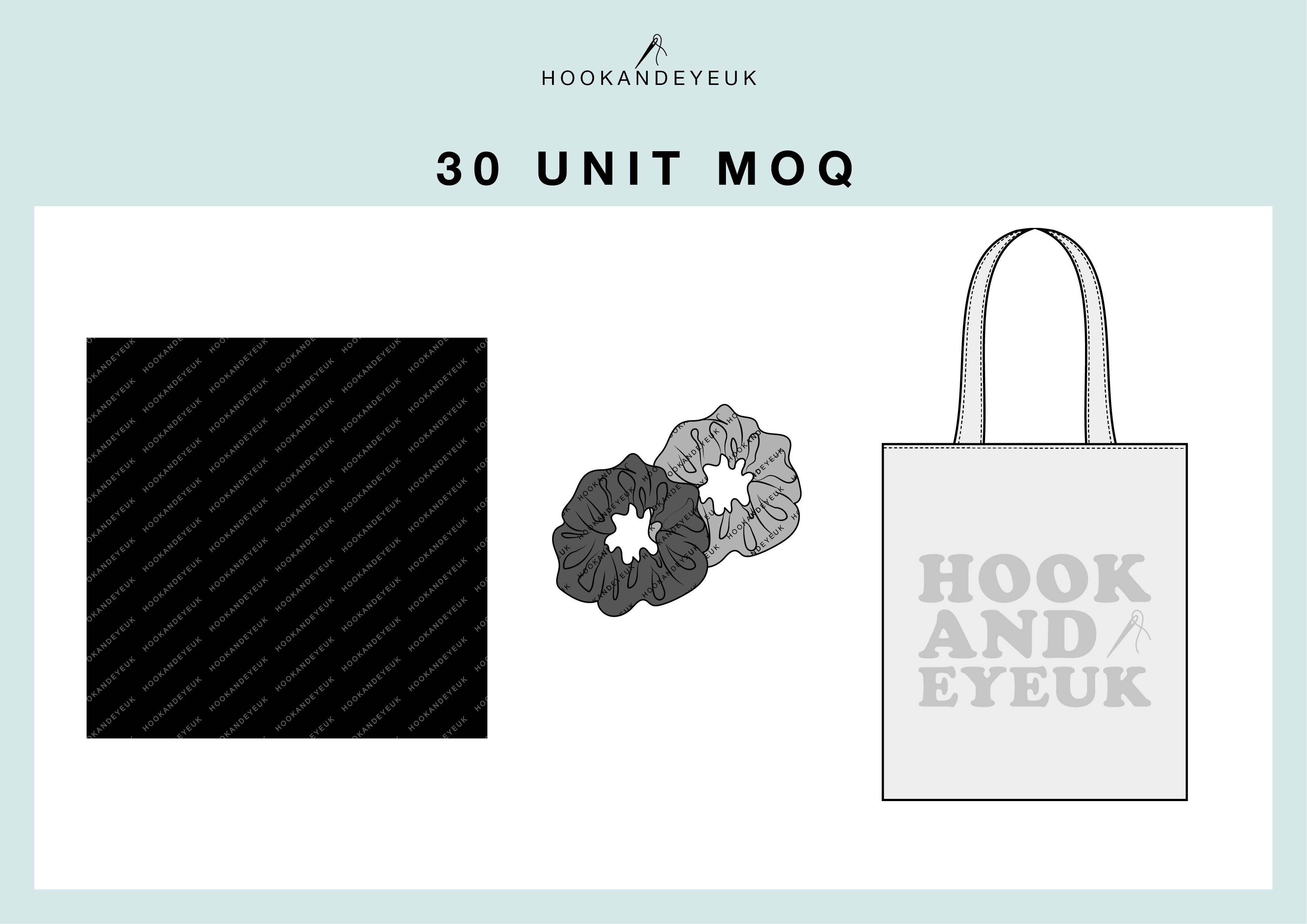

30 unit MOQ

Super simple items like printed silk scarves, scrunchies and tote bags, which have simple construction.

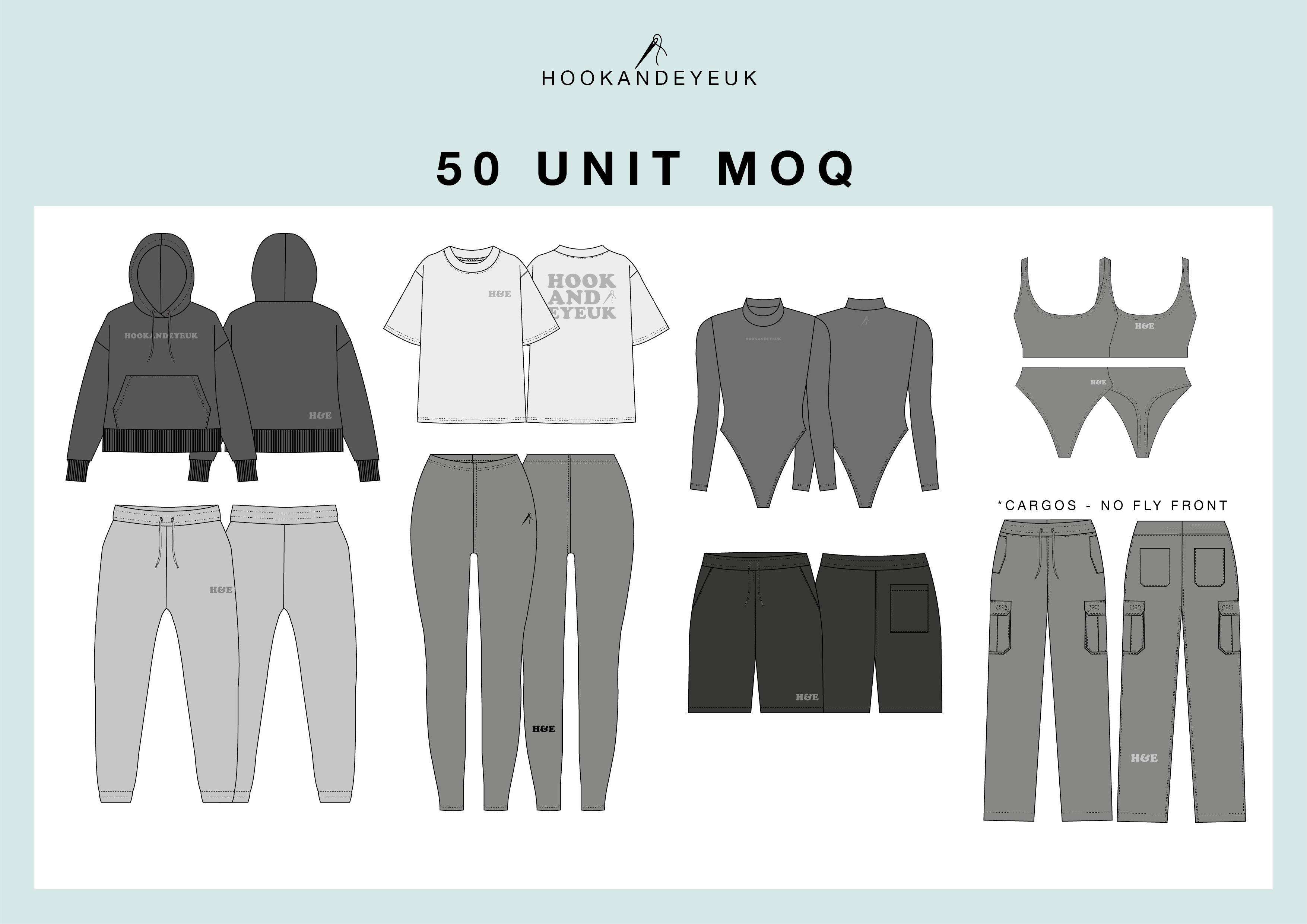

50 unit MOQ

Most lounge and essentials wear that we do falls under this category - hoodies, joggers, leggings, bodysuits, t-shirts and sweatshirts.

100 unit MOQ

Adding a fly-front zip (standard opening on jeans or trousers) to any trousers puts your MOQ up to 100 pieces, because it’s quite complicated to construct. Any knitted accessories such as socks, beanies and gloves also have an MOQ of 100.

Fabric & Material Choice — Effects on MOQ and Cost

Manufacturers don’t stock fabrics themselves, they source them from suppliers. Fabric suppliers have their own minimum order quantities of at least one roll of fabric per colour, which is usually 100 metres.

So therefore your garment order needs to use up at least the majority of that fabric roll. If you're making small items, like crop tops, for example, your MOQ per style may be increased because you essentially need to use up more fabric to absorb the cost of the fabric MOQ.

Prints, Embellishments & Graphics — When MOQ Jumps Up

Certain embellishments or graphic elements on your clothing designs require a higher MOQ, either because they require more set up work, or because they are more labour intensive to manufacture.

For example, adding appliqué to your design will push the MOQ up to 100 units. This is because the process of cutting the specific shapes, placing and stitching onto the garment is quite labour intensive. Sublimation print or reactive print (vibrant, all-over prints onto fabric), also have an MOQ of 100.

Adding lots of different graphic applications to your design may also raise the MOQ, as it will need to go through multiple processes and machines in the manufacturing process.

Read more about the different graphic application types and their pros and cons here.

How Order Quantity Affects Your Unit Cost — Why Larger Runs Are Cheaper

Something we often get asked is "why does the unit price decrease if I order bigger quantities?". It's because certain fixed costs for the manufacturer can be spread across more units, bringing the individual unit price down.

Fixed costs are things like pattern development, graphic set-up and manufacture set-up - factors that don't change no matter how many units you order.

Understandably most start-up brands prefer to launch with low units, until they build up a strong customer base and start to generate financial return. But if you're looking to reduce your unit price, ordering larger quantities can make a big difference.

(Tip - check out our blog post on 'The 'Cheapest' Way To Design Clothes' for more tips on minimising cost!)

What to Know About MOQs When Working With Hook and Eye UK

Here are a few key things to know about minimum order quantities, if you want to manufacture your clothing with us:

- The MOQ is per design and colour - meaning if your MOQ is 50, that's 50 units of each colour and each different graphic design. The MOQ can't be split across different colourways due to the fabric consumption.

- The MOQ is split across sizes - at Hook and Eye UK you can have a sizing split of up to 5 different clothing sizes in your bulk production, in whatever quantity split you want. E.g 10 small, 20 medium, 12 large and 8 XL = a total of 50 units.

- You need 2 different designs to sample and manufacture with us. This is the minimum amount required to move into sampling and production. This can be 2 completely different designs, or the same design in 2 different colours.

Conclusion — How to Use MOQ Knowledge to Plan Your Clothing Line

To sum up, for a clothing manufacturer, there is a lot of preparation, set-up and labour that goes into completing your order. Manufacturers have Minimum Order Quantities to make sure an order is big enough to make it worth them fulfilling.

As a general rule, higher quantities in bulk manufacture = a lower unit price. This is because fixed costs like set-up costs can be spread across more units.

The MOQ can change based on the garment type and the complexity of construction. It can also be affected by the fabric and graphic applications that you use.

It's really beneficial to bear MOQ's in mind when you're designing your clothing range, and consider what unit quantities you want to commit to, as certain design features and graphic applications can increase the MOQ per design.

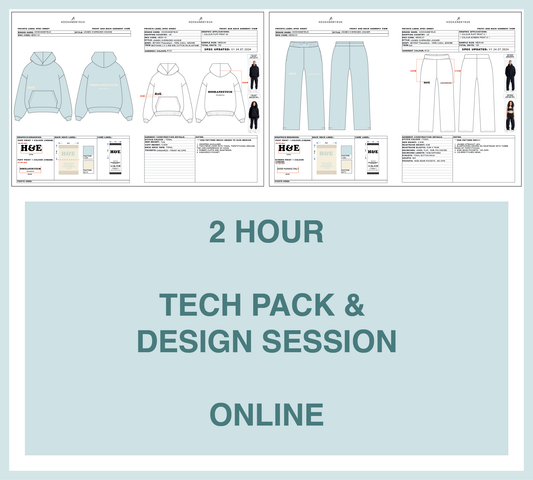

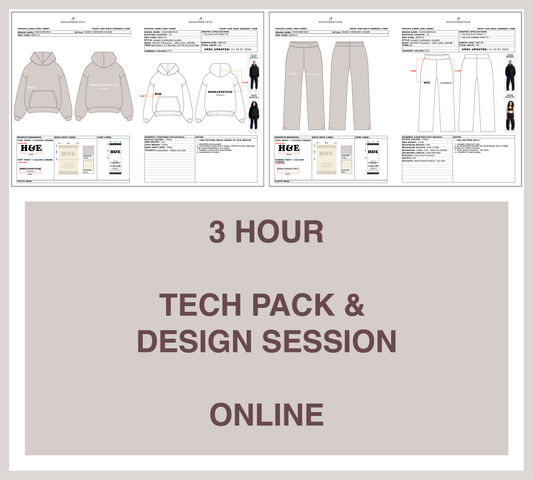

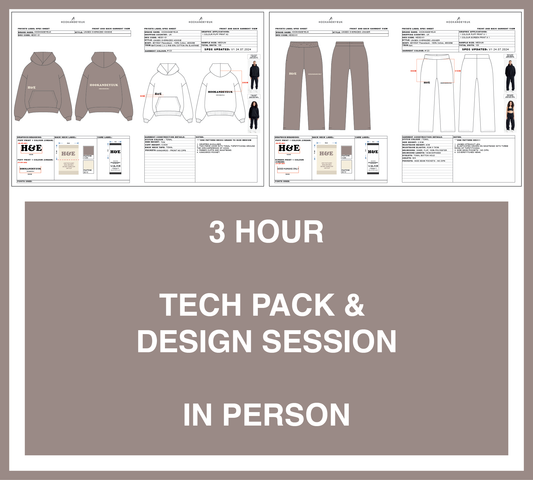

At Hook and Eye UK, our MOQ's generally starts at 50 units per design/colour, and our designers will always talk you through factors that affect MOQ in a tech pack and design session. A tech pack and design session is the perfect way to get your clothing brand off to the right start - if you'd like our expert design help, you can book a tech pack and design session here.

If you'd like to start a conversation about designs for your brand and what Minimum Order Quantities to expect, get in contact here.

Love, Bethany H&E xx

About the Author: Bethany is an experienced fashion designer at Hook and Eye UK, with a First-Class BA (Hons) degree in Fashion from the University of Northampton. She is the recipient of both the Fashanne East Midlands Design Award and the CORDURA Durable Design Award, recognising excellence in design and durability. Bethany began her career as a Design Assistant within the uniform industry, contributing to ranges for major brands including HSBC, EasyJet and Costa Coffee. She later worked as an Accessories Designer, creating licensed products for leading UK retailers such as Next, M&S and New Look. She joined Hook and Eye UK in November 2023.