At Hook and Eye UK, we believe quality isn't just the final step—it’s the foundation of every successful garment. Whether you're launching a new collection or scaling your production, having a strong quality control (QC) process is critical to ensuring consistency, consumer satisfaction, and brand trust.

Here’s our expert guide to the most important QC points to check during your garment production process.

Why Quality Control Matters

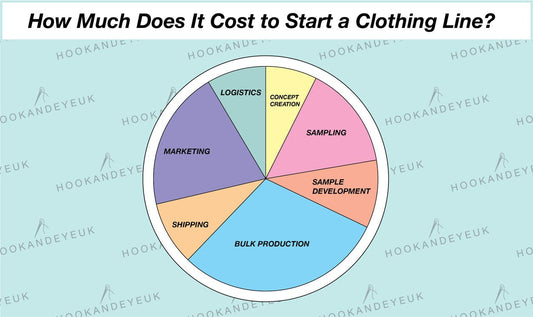

In today’s competitive fashion landscape, product quality goes beyond aesthetics. It's about delivering fit, function, and reliability in every piece. Poor QC can lead to costly returns, reputational damage, and loss of customer loyalty. A robust QC process ensures your garments consistently meet your specifications, perform as intended, and exceed customer expectations. This commitment to quality can lead to increased customer loyalty and a stronger brand reputation.

The Purpose of a Quality Control Checklist

A QC checklist is your production safety net. It serves as a standardised framework for inspections at every stage—ensuring your team can identify and resolve issues before they become expensive problems.

At Hook and Eye UK, we structure our QC process around key checkpoints that ensure every garment meets brand, retailer, and customer expectations.

A well-designed checklist can cover various aspects, including workmanship, fabric quality, sizing, and compliance with safety regulations.

Key QC Points to Check on Your Garment

1. General Information

Every garment should have a label or sticker that clearly indicates its style and size. This information is crucial for inventory management and helps in quickly identifying products during inspections. At Hook and Eye UK we put this sticker on the bags that the garment is packed into for ease, take a look at the image below you’ll see the sticker on the bottom right side of the garment bag!

2. Workmanship

Inspect the garment for any major faults in workmanship. Key areas to focus on include:

· Seams: Look for open or unfinished seams that could lead to garment failure.

· Graphics: Ensure that any printed or embroidered designs are correctly placed and free from defects.

· Finishing: Check for loose threads or unfinished edges that may affect the garment's appearance.

3. Measurement and Sizing

Accurate measurements are vital for ensuring a proper fit. Use your final bulk production measurements chart to check critical points like:

· Chest Width: Measure across the chest starting 2.5cm below the ‘armpit’ seam.

· High Shoulder Point to Hem: This measurement determines the length of the garment.

· Sleeve Length: Measure the shoulder from the seam to end of sleeve.

· In-seam: For trousers, measure from the crotch to the hem.

Remember to measure a garment properly it must be done in the exact place the chart specifies and always on a completely flat garment. Accurate garment measuring takes training so seek advice from a profession (like a garment developer or seamstress) if you’re unsure.

4. Fabric and Material

Verify that the fabric used matches the specifications outlined in the tech pack. This includes checking for:

· Composition: Ensure the fabric is made from the correct materials (e.g., cotton, polyester).

· Weight: The fabric should have the specified weight to ensure durability and comfort.

· Texture: Check for any inconsistencies in texture that could indicate poor quality.

5. Trims and Accessories

Trims such as buttons, zippers, and labels should also be inspected. Ensure that:

· Specifications Match: All trims should align with what is specified in the tech pack.

· Functionality: Zippers should operate smoothly, and buttons should be securely attached.

6. Packaging and Presentation

First impressions matter. The way garments are packaged can significantly impact their presentation. Check that:

· Packaging Materials: Ensure that the packaging is appropriate for the garment type and protects it during transit.

· Labelling: Labels should be clear and correctly positioned on the packaging.

7. Compliance and Safety

If your garments are subject to specific safety regulations, ensure that:

· Guidelines are met: Check that all safety standards have been adhered to, including flammability and chemical content.

· Certifications: Verify that any necessary certifications are in place.

8. Defect Classification

Establish a system for classifying defects to streamline the inspection process. Common classifications include:

· Critical Defects: Issues that pose safety risks or involve incorrect sizing/labelling.

· Major Defects: Visible flaws in fabric or construction that affect the garment's usability.

· Minor Defects: Small issues such as loose threads that do not significantly impact the garment's function.

9. Final Quality Checks and Inspection Results

Before garments are packed for shipment, conduct a final inspection to ensure:

· Overall Quality: The garment meets all specified quality standards.

· Correct Labelling: Ensure that all garments are labelled correctly for easy identification.

· After the inspection, document the results:

· Pass

· Fail

· Re-inspection required

10. Continuous Improvement and Traceability

Maintain detailed records of all QC processes from pre-production to post-production. This will help in:

· Identifying Trends: Spotting recurring issues can lead to better quality control practices.

· Staying Updated: Keeping abreast of new technologies and methods for detecting quality issues.

Partner With Hook and Eye UK for Seamless Quality Control

From tech pack creation and development to bulk production and QC checks, Hook and Eye provides end-to-end support designed to safeguard your garment quality—whether you're producing 100 units or 10,000. Our integrated UK and overseas teams work together to uphold premium quality standards across all stages of development.

Want fewer defects, stronger customer reviews, and more reliable production?

Let Hook and Eye handle the QC—so you can focus on growing your brand.

Get in touch with us today!

Hope you found this helpful,

H&E team :)