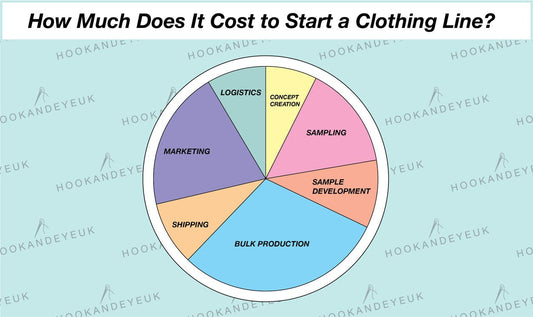

When it comes to big clothing brands, we often look at their collections and marvel at the creativity and variety in their ranges. But can you do that as a startup?

As a startup fashion brand, you don't have the buying scale of the big brands, so the question is - how can you build a clothing collection that's just as impressive as the big brands, but without breaking the bank?

First-off, it's not easy, but it is certainly achievable if you follow the right process. In this guide, we'll show you how to create clothing collections that are as good as big brands, without overspending.

Now, the challenge is that the big labels are buying in huge volumes, which helps to reduce their pricing, and makes having a varied range much easier.

So, if you're not ready to drop £150k on a huge clothing production, you'll probably have to go through a manufacturer that offers low minimum order quantity manufacturing (a.k.a. low MOQ manufacturing). The issue is, that most low MOQ clothing manufacturers have to cut a few corners and miss out a few steps to get your clothes made at the right price. Not surprisingly, that can cause can cause big problems for your garments, and for your brand.

So, that's why Hookandeyeuk offers a process that's the same for all brands, regardless of size, making sure that your brand is built on the right foundations, but without breaking the bank!

Let's run through how to do it...

HOW STARTUP BRANDS CAN DEVELOP HIGH-QUALITY CLOTHING RANGES IN THE MOST ECONOMIC WAY.

STEP 1: Get your tech packs done properly from the start

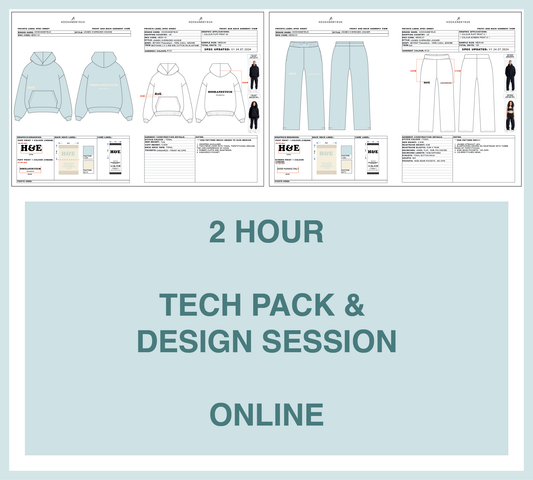

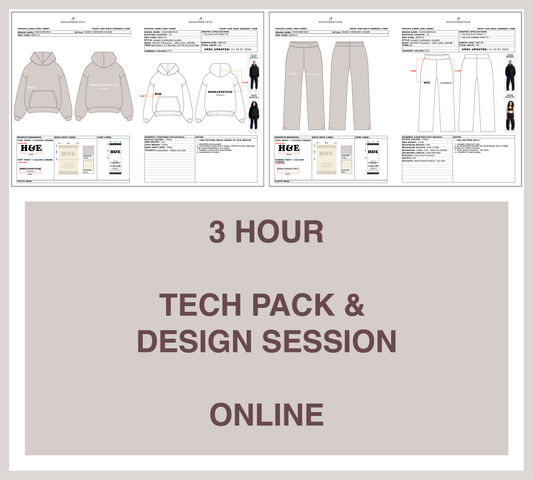

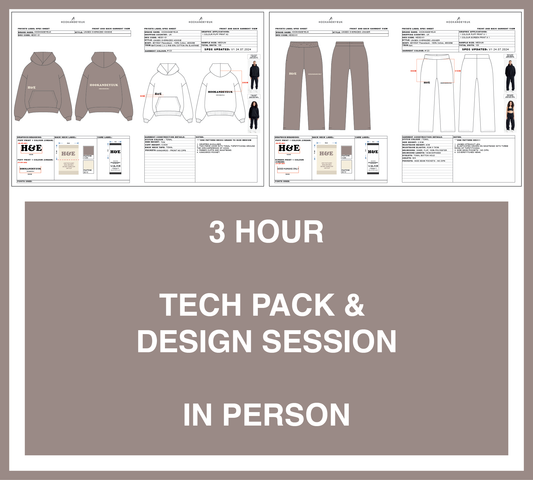

To design and develop a high-quality clothing line on a budget, the process always starts with getting your tech packs done properly, first time round.

Tech packs are essentially a full guide to the item of clothing you want to be sampled / bulk manufactured. Everyone in the clothing manufacturing chain relies on your tech packs for pricing, pattern cutting, sample making and bulk manufacture. So it's crucial to get your tech packs done properly.

The best starting point is to get a tech pack and design session booked with an expert. These sessions are designed to get your ideas put into fully usable & detailed tech packs.

At Hookandeyeuk, one of our lead designers runs the session with you, where they take your ideas (which can be image references found on the internet), and then produce drawings that they turn into tech packs in front of you, via zoom screen share.

In the session they will discuss fabric, colour, and garment construction options with you, helping you go from just an idea to having a fully developed tech pack.

Once you've got your tech packs created, we (or another clothing manufacturer for that matter!) can give you pricing estimates for having your garments made into samples, along with estimates for bulk production costs.

STEP 2: Leverage your previous collections

In the below image you can see that the first clothing collection (Drop 1) has been developed, and the second clothing collection (Drop 2) utilises the best selling pieces from the first range, just with a few additional items.

This is exactly what happens in the fashion industry. Big brands don't re-build everything from scratch. They use what sold best previously and re-design, keeping the same shape but using different fabrics and prints and adding a small percentage of new shapes to test the market each time.

This cycle repeats over and over with slight migration on colour and style.

Working in this way and leveraging all the hard work that you've already put in to your previous collections will save you hours of time, and lots of money when producing your new collections. It also ensures that you're developing on the items that sold best in the past, and are most likely to sell well in your next collection.

STEP 3: Plan Ahead!

To make sure you can manufacture a great clothing range in a cost-effective way, you have to be prepared.

As a rule of thumb, you need to make sure you're designing at least 2 seasons ahead so that you can utilise cheaper, more environmentally friendly shipping methods. (It also means you won't be rushing through the process, which helps you to avoid potentially costly errors).

The most economic shipping is sea freight and this is what is most commonly used in industry. But, given the longer shipping times, you can only use it if you've planned ahead properly.

Here's a quick breakdown of shipping timing & pricing:

You can see in the image above that sea shipment is the most cost-effective option.

This is why being prepared and designing your collections at least 6 months ahead really pays!

It allows you to utilise slower/ cheaper shipping methods, and when you're starting a fashion brand, making those savings can be the difference between turning a profit or not.

Sea freight is also less harmful to the planet than truck or air freight, and minimising our carbon footprint is something we should all strive for in the fashion industry.

STEP 4: Find an FPP Manufacturer to work with

FFP stands for Full Package Production and in the textile industry that means that the FPP clothing manufacturer takes care of all aspects of garment creation.

That means that they will be able to help you with everything from designing & tech pack creation (check out our tech pack and design sessions!), grading, pattern creation, fabric sourcing, sample production, sample reviews and tweaks for bulk production, bulk garment construction, garment packaging and delivery.

That's how we work at Hookandeyeuk.

The great thing about a good FPP manufacturer is that not only will it save you hours and hours of time not having to liaise with 6 or 7 different suppliers, their economies of scale across various brands means that you can get smaller clothing collections produced at the same price as much larger brands.

That means you can get your clothes made at the right price, with the correct foundations in place and have a varied and interesting range, without spending hundreds of thousands on a huge production.

STEP 5: Use the right design & manufacture process

At Hookandeyeuk, we've worked with hundreds of startup fashion brands, to design, manufacture and launch their clothing collections, and have developed a finely tuned process to ensure quality, speed and cost-effectiveness.

Here's the correct order and process for you to follow for your next clothing line:

1. Tech pack and design session (held between our head designer and you).

2. Sample and bulk manufacture costing (generally sent to you 3-5 working days after your tech pack and design session - unless you have specific fabric requests).

3. Sample invoice sent to you.

4. Once sample invoice payment is received: Paper patterns are made for each design and then digitised (patterns can be taken from reference samples or you can use our pre-developed shapes for fits).

5. Graphics applications are applied to fabrics and then sample construction is commenced.

6. Samples are finished, and quality checked and then sent to H&E for review.

7. Samples are sent to you for confirmation of bulk production.

8. A FREE development session is held between you and our garment developer Elina to discuss any minor tweaks to samples and finalise tech packs for bulk production.

9. Bulk production invoice is sent to you.

10. Once bulk production invoice payment is received: Bulk production is commenced, finished & quality checked and sent to you. You pay 60% deposit for bulk production up front and 40% on completion.

That's it, process complete!

And so that you've got an idea of timings, here are the typical estimated lead times:

- Sampling 6-8 weeks

- Bulk production 4-8 weeks + shipping

- Bulk production shipping: 2 weeks (*£££ express air) / 4-5 weeks (*££ truck) / 7-10 weeks for UK – 4 weeks for the USA (*£ sea).

By following this process, you'll be able to have your clothes designed, sampled and manufactured in a quick, efficient and high quality way.

IN CONCLUSION:

Creating high-quality, clothing collections for your startup brand doesn't have to break the bank. By following these tips and strategies, you can create affordable clothing collections that rival those of big brands:

Get your tech packs done right - Tech Packs are the cornerstone of a good clothing collection. Getting these done properly at the outset will save you so much time, frustration and money further down the line. (Click here to book a Tech Pack & Design Session with us)

Reuse and renew your collections - For each collection that you sell, ensure you take note of your best selling styles and update them for your next collection (as long as it's in season) by changing fabric colours and graphics.

Prepare - Make sure you're designing at least 2 seasons ahead so you can utilise cheaper, more environmentally friendly shipping methods (and you're not rushing through the process).

Find an FPP manufacturer - Working with a partner that can help you through the entire design & manufacture process will help to save you a lot of time and money.

Follow the right process - There's a right and a wrong way to manufacture your clothing collections. By following the order that we use at Hookandeyeuk, you'll make sure you're doing it right.

If you'd like some guidance from us on your next clothing collection, we'll be happy to help, just drop me a line on WhatsApp:

+447939591255

Love, Joss H&E xx

P.s. If you'd like to know about how to price your next collection properly - ask us to send you our 'Estimated Pricing Guide'. In this guide we tell you an estimated production price based on brands like Stussy, Palm Angels, Fear of God and Represent along with a RRP and estimated profit level - it's mega useful!