In today’s fast-moving garment industry, quality assurance (QA) isn’t just an option—it’s a necessity. Every brand wants to stand out for the right reasons, and the only way to do that is by making sure that the garments reaching customers are consistently high-quality, defect-free, and true to the brand’s vision.

At Hook and Eye UK, we know that the success of your clothing line depends on more than just design—it depends on execution. That’s why every single bulk manufacture we handle comes with a full Quality Assurance guide, limiting potential mistakes before they happen and protecting your investment at every stage of development.

This article explores what garment quality assurance really means, why it matters, and how our approach ensures that only the best products reach your customers.

Why Quality Assurance Matters in Fashion

Quality assurance is central to:

· Protecting your brand reputation – Customers quickly lose trust if garments arrive with defects, poor fit, or inconsistent finishes. High-quality garments foster loyalty and repeat sales.

· Reducing costs and waste – Identifying and fixing issues early prevents expensive rework, stock write-offs, and delivery delays.

· Ensuring compliance – From safety to environmental regulations, QA protects both your customers and your business from legal or ethical risks.

Hook and Eye’s Approach to Quality Assurance

At Hook and Eye UK, our UK team acts as your dedicated development partner, handling the details that bulk-only manufacturers often push back onto the brand. This includes:

· Tech pack updates

· Sample reviews & reports

· Construction and QC guideline checks

· Customer sample development sessions

· Ongoing communication between the UK and China manufacturing teams

With us, you’re not left to navigate the complexities alone—we integrate QA into the full development process.

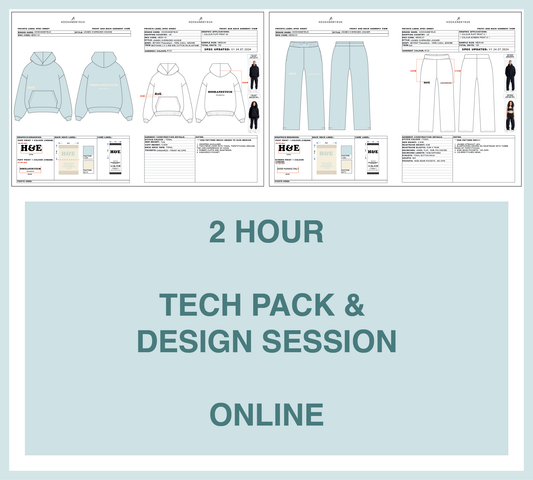

Above you can see an example of a Hook and Eye UK tech pack.

Key Components of Quality Assurance

1. Quality Standards and Specifications

Establishing clear quality standards is the foundation of any effective quality assurance programme. These standards should encompass various aspects, including:

· Material Quality: Ensuring that fabrics and components meet specified criteria.

· Fit and Size: Adhering to specific measurements and fit specifications to ensure customer satisfaction.

· Construction Quality: Evaluating stitching, seams, and overall garment construction.

2. Quality Control Checklists

A comprehensive quality control checklist is vital for effective communication between manufacturers, suppliers, and quality control teams.

This checklist should include:

· Product requirements

· Packaging specifications

· On-site testing procedures

By utilising a checklist, teams can ensure that every aspect of the garment meets the established standards.

3. Laboratory Testing

Laboratory testing is a crucial component of quality assurance, this is proformed on all fabrics used. It involves assessing the safety, compliance, and performance of fabrics through various tests, such as:

· Colorfastness: Ensuring that colors do not fade or bleed during washing.

· Flammability: Testing fabrics for their resistance to ignition.

· Durability: Evaluating how well the fabric withstands wear and tear.

These tests help manufacturers identify potential issues before garments reach consumers.

The Role of Quality Assurance in the Supply Chain

Quality assurance extends beyond the manufacturing floor; it encompasses the entire supply chain. Effective QA practices involve collaboration with suppliers to ensure that raw materials meet quality standards. This collaboration can include:

· Supplier Audits: Regular assessments of suppliers to ensure compliance with quality standards.

· Training and Development: Providing training to suppliers on quality expectations and best practices.

By fostering strong relationships with suppliers, companies can enhance the overall quality of the garments produced.

Implementing a Quality Assurance Programme

1. Developing a Quality Assurance Framework

Creating a robust quality assurance framework is essential for effective implementation. This framework should include:

· Standard Operating Procedures (SOPs): Detailed guidelines for every stage of production.

· Training Programs: Regular training for employees on quality standards and inspection techniques.

· Feedback Mechanisms: Systems for collecting and analysing customer feedback to identify areas for improvement.

2. Strengthening Quality Control Efforts

To ensure that high-quality products reach consumers, companies should implement rigorous quality control measures, including:

· Regular Inspections: Conducting inspections at various stages of production to identify defects early.

· Random Sampling: Using accepted sampling methodologies to verify the quality of finished products.

3. Leveraging Technology

Incorporating technology into quality assurance processes can significantly enhance efficiency. Tools such as:

· Data Analytics: Analysing production data to identify trends and potential issues.

· Automated Inspection Systems: Using technology to streamline inspections and reduce human error.

These advancements can lead to more accurate assessments and quicker resolutions of quality issues.

Challenges in Quality Assurance

Despite its importance, implementing effective quality assurance can be challenging. Some common obstacles include:

· Variability in Production: Inconsistent quality across different production runs can lead to customer dissatisfaction.

· Lack of Transparency: Limited visibility into the supply chain can hinder quality control efforts.

· Balancing Speed and Quality: The pressure to meet tight deadlines can sometimes compromise quality standards.

Addressing these challenges requires a commitment to continuous improvement and a proactive approach to quality management.

Continuous Improvement in Quality Assurance

Quality assurance is not a one-time effort; it requires ongoing evaluation and improvement. Companies should regularly review their quality assurance processes and seek opportunities for enhancement. This can involve:

· Benchmarking Against Industry Standards: Comparing practices with industry leaders to identify areas for improvement.

· Implementing Feedback Loops: Establishing mechanisms for gathering feedback from employees and customers to inform quality initiatives.

By fostering a culture of continuous improvement, companies can adapt to changing market demands and maintain high-quality standards.

Final Thoughts

In fashion, quality is your reputation. By investing in a structured QA process, you protect your brand, save money, and build lasting customer trust.

At Hook and Eye UK, our tech pack solutions and integrated QA processes ensure that your garments are designed, sampled, and produced to the highest standards—without the stress of managing it all yourself.

Ready to elevate your garment quality assurance?

Explore our Tech Pack Services or get in touch with our team today to discuss how we can help your brand deliver premium-quality garments, every time.

Hope you found this helpful,

H&E team :)