Waste in fashion manufacturing is harmful to the environment and bad for businesses. Reducing waste starts with thoughtful design and collaboration. From the beginning, always consider how you make your product. By working closely with professionals and production teams, you can reduce waste and create a more efficient and greener fashion manufacturing process.

Step 1: Start with Clear Goals

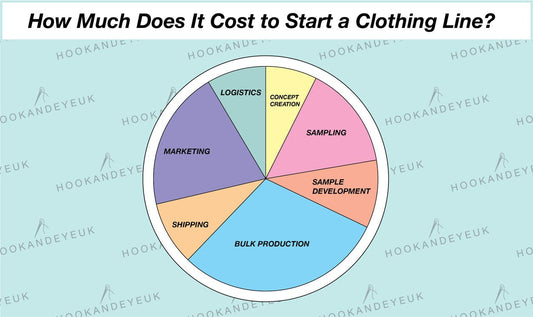

Set your sustainability and production goals early. Whether you aim to reduce the number of samples, minimise fabric waste, or lower your carbon footprint, a transparent work process lays the groundwork for success. Clear goals and an understanding of what you want will help you make informed decisions in the later stages of production.

Step 2: Collaborate Early and Promptly

Now that you have set your goal, bring together your design, development, and production teams, review everything together, and address any potential design issues or problems that could delay production. Early collaboration minimises miscommunication, reduces revisions, and ensures everyone shares sustainable goals.

Step 3: Design for Manufacturability

To produce your garment sustainably and efficiently, design digitally using CAD and develop a full, detailed tech pack with clear instructions and technical guidance. (Click here to learn more about the design and tech pack session.) Meanwhile, get the factory involved in reviewing your design to get feedback early and avoid unnecessary complexity.

Step 4: Digital pattern cutting

Use clever pattern cutting and garment construction techniques to reduce material waste and samples. Using advanced CAD digital software that assures efficiency and precision while being cost-effective in modern fashion production.

Step 5: Choose High-Quality & Sustainable Materials

Most importantly, choose high-quality, sustainable fabric that last! (Click here to learn more about fabrics). Especially for small start-ups, the best option is to select what is readily available to avoid delays and creating deadstock. In contrast, big brands often have the financial resources to develop and design their fabrics; this option is not likely accessible for small brands, as you will need to commit to extremely large order quantities.

Summary

Garment manufacturing is a human process and certainly not perfect. However, following the abovementioned practices allows us to produce garments sustainably, creating high-quality products while reducing waste more efficiently.

What We Do at Hook and Eye UK

At Hook and Eye UK, we pride ourselves on not offering 'fast fashion' garment manufacturing and endeavour to reduce waste consistently within all our processes. We aim to get your sample as close to perfect as possible in the first round, reducing both financial and textile waste.

For example, some of the things we offer include:

- Industry-standard developers trained in advanced pattern cutting and garment construction.

- Free development sessions to discuss design and sampling adjustments to minimise errors in the production stage.

- Quality control at every stage of production.

- Innovative solutions that reduce the number of samples needed and improve manufacturing efficiency.

- Bulk manufacture unit quantities run on a +/-5% system to allow for the least garment and fabric wastage possible.

Contact us here to learn how we can help you create a more responsible fashion future.

Love Team, Hook and Eye UK